Top 10 Tips for Implementing Robotic Systems in Your Business Successfully

In today’s fast-paced industrial landscape, the integration of robotic systems has become a pivotal element for businesses aiming to enhance efficiency and remain competitive. As organizations strive to streamline operations and improve productivity, the adoption of automation technologies presents both incredible opportunities and notable challenges. Successfully implementing robotic systems requires a strategic approach that considers not only the technical specifications but also the human factors that influence the deployment and effectiveness of these technologies.

This article will delve into the top 10 tips for successfully integrating robotic systems into your business operations. From understanding the specific needs of your organization to ensuring proper training and support for your workforce, these insights will provide a comprehensive roadmap for maximizing the benefits of automation. By prioritizing thoughtful planning and execution, businesses can navigate the complexities of robotic integration and ultimately drive innovation and growth in their respective industries.

Understanding the Importance of Robotic Systems in Business Operations

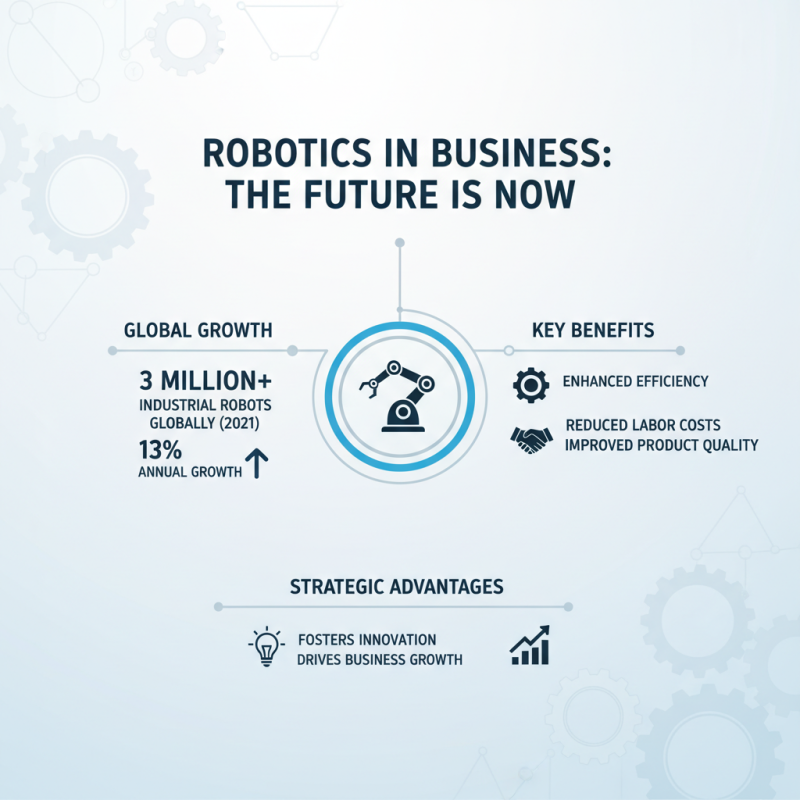

The integration of robotic systems into business operations has become increasingly vital in today’s competitive landscape. According to the International Federation of Robotics, the global stock of industrial robots reached approximately 3 million units in 2021, with a growth rate of around 13% annually. This surge highlights not only the growing trust in robotic automation but also its potential to enhance efficiency, reduce labor costs, and improve product quality. By automating routine tasks, businesses can redeploy human resources to more strategic areas, thereby fostering innovation and growth.

Moreover, businesses that adopt robotic systems are often better positioned to meet market demands. A report from McKinsey reveals that companies utilizing advanced robotics can increase productivity by up to 30% and significantly shorten production cycles. This efficiency translates into faster delivery times, which is crucial in a world where customer expectations are constantly rising. The implementation of robotic systems enables real-time data collection and analysis, further optimizing operational processes and decision-making. As organizations embrace these technologies, the importance of not just adopting robotics but doing so strategically becomes clear—a move that can redefine their competitive edge in the marketplace.

Assessing Your Business Needs and Goals for Robotic Integration

When implementing robotic systems in a business, it is crucial to first assess the specific needs and goals of the organization. A comprehensive analysis can reveal operational bottlenecks, inefficiencies, and areas where automation can yield significant benefits. According to a report by the International Federation of Robotics, industries that effectively integrate robots can see productivity increases of up to 30%, demonstrating that a targeted approach to robotic deployment can lead to substantial performance enhancements. Understanding the unique workflows and challenges of your business can aid in determining the best robotic solutions to pursue.

Additionally, aligning robotic integration with broader business objectives is essential for success. A survey conducted by McKinsey & Company found that over 60% of companies that automated their processes reported a strategic advantage over competitors. By clearly defining goals—such as reducing operational costs, increasing output quality, or enhancing customer service—businesses can create a roadmap for robotics integration that not only addresses current issues but also supports future growth. This alignment ensures that the investment in robotic technology is not just a tactical move but a strategic lever that propels the organization towards its long-term vision.

Choosing the Right Robotic Technology for Your Industry

Choosing the right robotic technology for your industry is crucial for maximizing efficiency and ensuring a seamless transition into automation. Each sector has unique requirements that can significantly influence the effectiveness of robotic systems. For instance, in manufacturing, industrial robots are ideal for repetitive tasks such as assembly, welding, and packaging due to their precision and speed. On the other hand, service industries may benefit more from collaborative robots, or cobots, which can work alongside human workers to enhance productivity in tasks such as customer service or food preparation.

Before implementing any robotic technology, it's essential to assess the specific challenges and objectives of your business. Conduct a thorough analysis of your workflows to identify areas where robotics can provide the most value. Consider factors such as the layout of your workspace, the complexity of the tasks, and the level of human interaction required. Additionally, keep in mind the importance of scalability; choose a robotic solution that can grow with your business and adapt to future technological advancements. By aligning the chosen technology with the particular needs of your industry, you can ensure a higher return on investment and a smoother integration process.

Top 10 Tips for Implementing Robotic Systems in Your Business Successfully

| Tip Number | Tip Description | Industry Suitability | Robotic Technology Type |

|---|---|---|---|

| 1 | Conduct a thorough needs assessment to identify business processes that can be improved. | Manufacturing | Industrial Robots |

| 2 | Engage stakeholders early in the process to gather diverse insights and gain support. | Logistics | Automated Guided Vehicles (AGVs) |

| 3 | Research different robotic technologies and their applications in your sector. | Healthcare | Surgical Robots |

| 4 | Plan for integration with existing systems to ensure seamless operation. | Food Production | Collaborative Robots (Cobots) |

| 5 | Implement a pilot program to test the robotic system on a smaller scale before full deployment. | Retail | Service Robots |

| 6 | Offer training to employees to ensure they understand how to work alongside robots. | Warehouse | Robotic Picking Systems |

| 7 | Evaluate performance metrics regularly to measure effectiveness and efficiency. | Construction | Drones and Autonomous Machinery |

| 8 | Stay updated on technological advancements to leverage new capabilities. | Education | Educational Robots |

| 9 | Ensure compliance with regulations related to robotic systems in your industry. | Pharmaceutical | Robotic Dispensing Systems |

| 10 | Foster a culture of innovation that embraces technology and adapts to changes. | Telecommunications | Robotic Process Automation (RPA) |

Creating a Detailed Implementation Plan for Robotic Systems

Creating a detailed implementation plan for robotic systems is crucial for businesses seeking to harness automation effectively. According to a report by McKinsey, companies that adopt robotic automation can see labor cost reductions of up to 30% within the first 2-3 years of implementation. To achieve such results, businesses must outline clear goals and objectives during the planning phase. This includes defining specific tasks that will be automated, setting performance metrics, and identifying potential challenges that may arise during the transition.

A well-structured roadmap should encompass all stages of implementation, from initial assessments to post-deployment evaluations. The International Federation of Robotics indicates that in 2022, the average investment in robotics and automation technology was about $150,000 per system, emphasizing the need for businesses to budget adequately. Additionally, engaging employees in the planning process can facilitate smoother integration, as staff who are informed and involved are more likely to embrace new technologies. Continuous training and support are also vital to ensure that both the technology and the workforce can adapt effectively, minimizing downtime and resistance to change.

Top 10 Tips for Implementing Robotic Systems Successfully

Training and Supporting Employees During the Transition to Automation

Transitioning to automation can be intimidating for employees, but providing robust training and support can ease this process significantly. When implementing robotic systems in your business, it’s crucial to develop a comprehensive training plan that addresses the needs of all staff members. Start by creating a detailed curriculum that outlines the functionalities of the new systems and how employees can collaborate with them effectively. Allow employees to engage in hands-on training sessions, where they can experiment with the robotic systems in a controlled environment, fostering comfort and confidence.

To ensure ongoing support, establish a feedback loop where employees can voice their concerns and share suggestions during the transition. This involvement not only helps in identifying potential issues early but also empowers employees to take ownership of their roles alongside new technologies. Complement this by appointing ‘automation champions’ within teams—enthusiastic individuals who can provide peer support and facilitate knowledge sharing. This approach promotes a collaborative atmosphere, helping staff adapt their skills while reinforcing the value of technology as an ally rather than a replacement.

Encouraging a culture of continuous learning is key. Offer refresher courses and advanced workshops as the technology evolves, ensuring employees always feel equipped to handle their tasks efficiently. By instilling a positive outlook towards automation and providing the necessary tools and support, your workforce will not only adapt but thrive in an automated environment.

Related Posts

-

Unlocking the Future of Work with Robotics and Automation Trends and Innovations in 2023

-

What is Robot Technology and How is it Transforming Our Lives Today

-

What is Robotics and Automation Driving the Future of Industry with 25 Percent Growth by 2025

-

10 Best Robotics Automation Trends Transforming Industries in 2023

-

2025 How to Master Advanced Robotics: Explore Trends, Tips, and Techniques

-

What is Robotics Engineering Courses and How to Choose the Right One