10 Essential Tips for Implementing Cobots in Manufacturing for Maximum Efficiency

In the rapidly evolving landscape of manufacturing, the integration of collaborative robots, or cobots, has emerged as a game changer for enhancing operational efficiency. Industry expert Dr. Emily Roberts, a leading figure in robotics innovation, emphasizes the significance of this technological advancement, stating, “The future of manufacturing lies in the seamless collaboration between humans and cobots, where together they can achieve unprecedented productivity.” This speaks volumes about the critical role cobots in manufacturing play in streamlining processes and improving overall output.

To fully leverage the potential of cobots, manufacturers must adopt strategic approaches that align with their specific operational goals. Implementing cobots in manufacturing not only involves selecting the right technology but also understanding the dynamics of human-robot interaction. By following key tips and practices, companies can ensure that their cobot integration is not only efficient but also enhances worker safety and satisfaction. As we delve into these essential guidelines, the focus will be on maximizing efficiency while harnessing the unique advantages that cobots bring to manufacturing environments.

Understanding the Role of Cobots in Modern Manufacturing Environments

In modern manufacturing environments, collaborative robots, or cobots, play a crucial role in enhancing productivity and efficiency. These robots are designed to work alongside human operators, seamlessly integrating into production lines while taking on repetitive and physically demanding tasks. By relieving workers from monotonous duties, cobots allow them to focus on more complex and creative responsibilities, thereby improving job satisfaction and operational effectiveness.

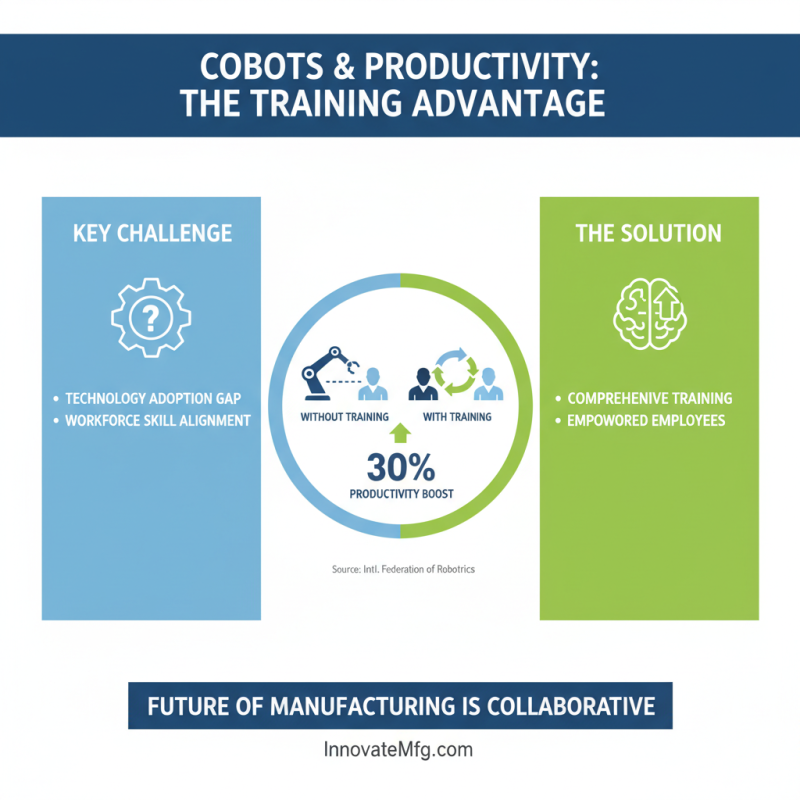

To successfully implement cobots, it's essential to ensure proper training for your workforce. When employees are familiar with how to work alongside these robots, they can maximize the benefits of collaboration. Additionally, investing in user-friendly interfaces and intuitive controls can further ease the transition, making it easier for staff to adapt to their new robotic partners.

Another vital tip for maximizing efficiency with cobots is to conduct a thorough analysis of your workflows before integration. Identify tasks that would benefit from automation, and strategically place cobots where they can provide the most value. By systematically mapping out processes, manufacturers can ensure that cobots enhance efficiency rather than complicate operations, leading to a more productive and harmonious working environment.

Efficiency Improvement with Cobots in Manufacturing

Key Metrics for Assessing Cobot Impact on Production Efficiency

When integrating collaborative robots (cobots) into manufacturing processes, assessing their impact on production efficiency is critical. Key metrics for evaluation include operational speed, task cycle time, and overall equipment effectiveness (OEE). According to a report from the International Federation of Robotics, manufacturers that implemented cobots experienced an increase in operational speed by up to 30%. This boost allows facilities to meet higher production demands without compromising quality.

Additionally, measuring task cycle time can provide insights into how cobots streamline processes. A study by McKinsey illustrates that automating repetitive or ergonomically challenging tasks can reduce cycle times by 20-50%, enabling human workers to focus on more complex, value-added activities. Monitoring OEE, which factors in availability, performance, and quality, is also crucial. Research indicates that companies using cobots tend to see improvements in OEE scores by approximately 15%, highlighting not only enhanced productivity but also reduced downtime and enhanced quality control.

Utilizing these metrics allows manufacturers to fine-tune their cobot implementations, ensuring maximum efficiency and aligning operational goals with technological advancements. As the landscape of manufacturing evolves, establishing these performance benchmarks will be vital for companies seeking to leverage cobots for competitive advantage.

Integrating Cobots: Overcoming Common Implementation Challenges

Integrating collaborative robots, or cobots, into manufacturing environments presents several challenges that can hinder their successful implementation. One of the primary hurdles is workforce adaptation. Employees may feel threatened by the introduction of cobots, fearing job displacement or changes in their roles. To mitigate these concerns, it is essential to involve workers early in the implementation process. Providing training and clear communication about how cobots will complement human tasks can foster a collaborative atmosphere, encouraging a smoother transition to automated processes.

Another significant challenge lies in the technical aspects of integration. Ensuring that cobots operate seamlessly alongside existing machinery and processes requires careful planning and expertise. Organizations should conduct thorough assessments of their current workflows to identify areas where cobots can be most effective. Additionally, a trial period with selected processes can help identify potential technical issues and allow for necessary adjustments. Collaborating with technical experts during the setup phase can also enhance the integration process, leading to improved efficiency and productivity within the manufacturing environment.

Training and Workforce Adaptation for Effective Cobot Utilization

In the rapidly evolving landscape of manufacturing, collaborative robots (cobots) are becoming pivotal for enhancing efficiency and productivity. However, the successful implementation of cobots is heavily reliant on effective training and workforce adaptation. According to a report by the International Federation of Robotics, companies that invest in comprehensive training programs for their staff witness productivity increases of up to 30%. This highlights the necessity of aligning employee skills with the capabilities of cobots, ensuring that workers are comfortable and proficient in interacting with these advanced machines.

Effective workforce adaptation involves not just technical training but also fostering a culture of collaboration between human workers and cobots. A study from the Massachusetts Institute of Technology found that operations where employees are actively engaged in the integration process of cobots report a 25% higher job satisfaction rate. This engagement not only empowers workers but also minimizes resistance to change, creating an environment conducive to innovation. By prioritizing training and adaptive strategies, manufacturers can maximize the benefits of cobots, driving both operational efficiency and employee morale.

Evaluating Return on Investment: Cobots vs. Traditional Automation

Evaluating the return on investment (ROI) for collaborative robots (cobots) compared to traditional automation methods is crucial for manufacturing businesses looking to enhance efficiency. According to a report by the International Federation of Robotics, the global market for cobots is expected to reach $12 billion by 2025, reflecting their growing prominence in the manufacturing landscape. Cobots offer a lower initial investment and reduced operational costs, making them an attractive option for smaller manufacturers or those hesitant to commit to the higher capital expenditures often associated with traditional robotic systems.

In assessing ROI, it's essential to consider not only the initial investment but also the flexibility and adaptability that cobots bring. A study from the Association for Advancing Automation indicates that companies utilizing cobots can achieve a payback period of as little as 12 months, significantly shorter than the 2-3 years typical for conventional automation. Furthermore, cobots can be reprogrammed for different tasks, which allows manufacturers to quickly pivot in response to changing market demands. This adaptability not only improves operational efficiency but also contributes to a more resilient and competitive manufacturing environment. Through careful analysis and comparison, manufacturers can leverage the advantages of cobots to maximize their overall efficiency and return on investment.

10 Essential Tips for Implementing Cobots in Manufacturing for Maximum Efficiency - Evaluating Return on Investment: Cobots vs. Traditional Automation

| Aspect | Cobots | Traditional Automation |

|---|---|---|

| Initial Investment | $35,000 | $150,000 |

| Payback Period | 12 months | 24 months |

| Flexibility | High | Low |

| Integration Ease | Easy | Complex |

| Training Requirements | Minimal | Extensive |

| Operational Costs | $5,000/year | $20,000/year |

| Space Requirements | Small | Large |

| Safety Features | Collaborative | Guarded |

| Production Speed | Moderate | High |

| Scalability | High | Moderate |

Related Posts

-

How to Choose the Right Automation Systems for Your Business Efficiency

-

What is Robotics and Automation Driving the Future of Industry with 25 Percent Growth by 2025

-

Understanding Robotic Process Automation and Its Impact on Business Efficiency

-

2025 How to Choose the Right Collaborative Robot Arm for Your Business

-

Unleashing Creativity in Robotics Engineering Courses for Future Innovators

-

Top 2025 Trends in Robotic Process Automation You Need to Know