How to Choose the Right Robot Machine for Your Business Needs?

Choosing the right robot machine for your business needs is a crucial decision that can significantly impact your operational efficiency and productivity. As industries increasingly adopt automation technologies, understanding the various configurations and capabilities of robot machines becomes essential. Whether you are seeking solutions for manufacturing, logistics, or service industries, the appropriate robot machine can streamline processes, reduce labor costs, and enhance precision in tasks.

In this guide, we will explore the vital considerations you must keep in mind when selecting a robot machine tailored to your specific requirements. Factors such as the type of tasks to be automated, the workspace available, and the integration with existing systems will influence your choice. By evaluating these elements logically, you can make an informed decision that not only meets your immediate needs but also positions your business for future growth through technological advancement. Embracing the right robot machine can ultimately transform your operational landscape and propel your business forward in an increasingly competitive environment.

Understanding Your Business Requirements for Automation

When selecting the appropriate robotic machine for your business, it is crucial to first understand the specific automation requirements of your operations. A recent trend report highlights that the workflow automation and optimization software market is projected to reach $1.397 billion by 2024, with an impressive growth expected to $3.741 billion by 2032. This significant compound annual growth rate (CAGR) of 13.1% underscores the increasing demand for efficient automation solutions across various sectors. Therefore, identifying the unique processes within your business that can benefit from automation is essential for achieving operational efficiency and cost savings.

In addition, aligning your business goals with the right technology is vital. For instance, the robotic process automation (RPA) market is experiencing robust growth as more organizations recognize the value of automating repetitive tasks. By understanding the nuances of your business needs—whether it involves data integration, governance, or process optimization—you can make informed decisions about the types of robotic machines or software that will provide the maximum return on investment.

Evaluating your existing workflows and pinpointing areas for improvement can guide you toward the most suitable automation solutions tailored for your business objectives.

Identifying Different Types of Robot Machines Available

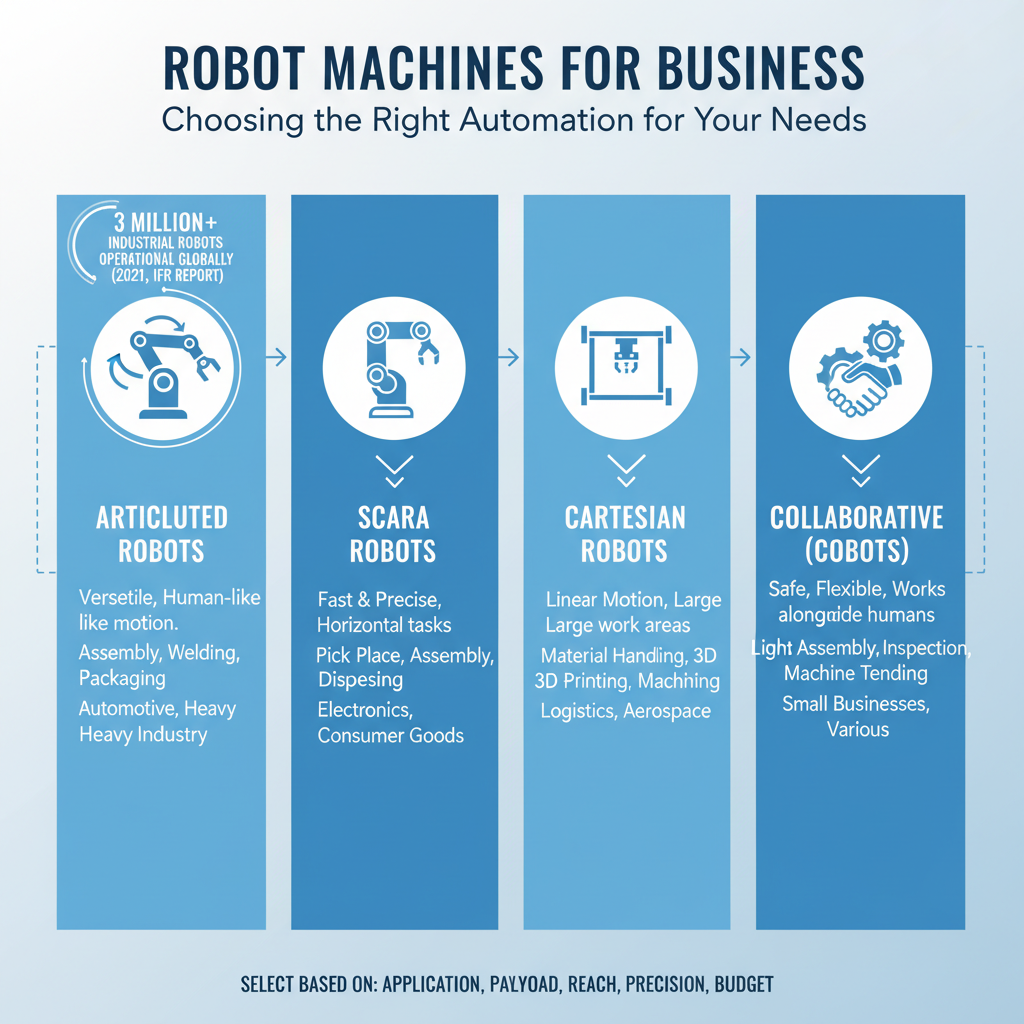

When selecting the right robot machine for your business needs, it is essential to understand the different types available in the market. According to a report by the International Federation of Robotics (IFR), the global stock of operational industrial robots reached approximately 3 million units in 2021, showcasing the growing reliance on automation in various industries. The main categories include articulated robots, SCARA robots, Cartesian robots, and collaborative robots (cobots), each serving distinct functions and industries.

Articulated robots, characterized by their flexible arms, are commonly used in automotive and manufacturing sectors for tasks such as welding and assembly, offering high precision and versatility. In contrast, SCARA robots excel in high-speed assembly lines where horizontal movement is critical, while Cartesian robots are favored for their straightforward operation in pick-and-place tasks across packaging and material handling. Meanwhile, the rise of collaborative robots has revolutionized production floors by working alongside human workers, enhancing efficiency and safety, as highlighted in the ABI Research report, which projected the cobot market to reach $12 billion by 2025. Understanding these categories will enable businesses to align their operational needs with the most suitable robot technology.

Evaluating the Compatibility of Robots with Existing Systems

When choosing the right robot machine for your business needs, evaluating compatibility with your existing systems is crucial. The integration of new robotic technology into current workflows can significantly impact productivity and efficiency. Begin by assessing the technological infrastructure already in place, such as software platforms, hardware specifications, and communication protocols. This understanding will help identify robotic solutions that can seamlessly align with your operations.

Additionally, consider the interoperability of the robot with existing machinery and tools. Robotic systems that offer flexible interfaces or are designed with adaptability in mind can save time and resources during implementation. Conducting a thorough analysis of how the robotic machine interacts with your current processes will not only minimize disruption but also maximize the potential for enhanced performance. Engaging with vendors who provide demonstration units or trial periods can further assist in evaluating compatibility before making a significant investment.

How to Choose the Right Robot Machine for Your Business Needs? - Evaluating the Compatibility of Robots with Existing Systems

| Robot Type | Compatibility Rating (1-10) | Key Features | Estimated Cost ($) | Recommended Use Case |

|---|---|---|---|---|

| Industrial Robot | 9 | High payload, precision movement, programmable | 50,000 | Manufacturing, assembly lines |

| Collaborative Robot | 8 | Safety features, ease of use, flexible | 30,000 | Small to medium-sized enterprises |

| Mobile Robot | 7 | Autonomous navigation, sensor integration | 40,000 | Warehousing, logistics |

| Service Robot | 6 | User interaction, mobility | 20,000 | Hospitality, healthcare |

| Drones | 8 | Aerial imaging, delivery | 15,000 | Agriculture, mapping |

Weighing Costs and Budget Considerations for Robot Acquisition

When considering the acquisition of a robot machine for business operations, understanding costs and budget considerations is crucial. According to the International Federation of Robotics, the global market for industrial robots was valued at over $14 billion in 2020, with a projected growth rate of 13% annually through 2025. This statistic underscores the importance of evaluating not only the initial purchase price but also the long-term return on investment (ROI) that these machines can offer.

Budgeting for robot acquisition involves assessing various costs beyond just the purchase price. Maintenance, training, and potential downtime need to be integrated into the overall financial plan. A report from McKinsey highlights that companies can save up to 20% on operational costs by implementing automation solutions. Furthermore, as many robots require software updates and regular maintenance, it is vital for businesses to factor in these ongoing expenses. By carefully analyzing the total cost of ownership, companies can make informed decisions that align with their operational goals and budgetary constraints.

Cost Comparison of Different Robot Machines for Business Needs

This bar chart illustrates the cost comparison of different types of robot machines suitable for various business needs. Understanding these costs is crucial for budget considerations when acquiring new robotic solutions.

Assessing Vendor Support and Maintenance Services for Robotics

When selecting the right robot machine for your business, assessing vendor support and maintenance services is crucial to ensure long-term operational success. A recent industry report from the International Federation of Robotics highlights that companies leveraging robotic solutions report a 30% increase in productivity within the first year. However, such success heavily relies on the quality of vendor support. Frequent updates, immediate technical assistance, and comprehensive training programs can significantly affect how effectively a business can integrate and utilize robotics.

Moreover, approximately 25% of all robotics failures can be traced back to insufficient maintenance or lack of timely vendor support, according to a study by McKinsey & Company. Thus, when evaluating potential vendors, businesses should prioritize those that offer robust service networks, quick response times, and transparent maintenance plans. This thorough assessment not only mitigates downtime but also enhances overall system reliability, contributing to the ROI of robotics investment. Focusing on vendor support ensures that businesses can adapt to evolving technologies and maintain a competitive edge in the increasingly automated landscape.

Related Posts

-

2025 How to Choose the Right Collaborative Robot Arm for Your Business

-

Exploring the Future: How Robotics Software is Transforming Modern Industries

-

What is Robotics Software? Understanding Its Benefits and Applications

-

Unleashing Creativity in Robotics Engineering Courses for Future Innovators

-

What is Robotics and Automation Driving the Future of Industry with 25 Percent Growth by 2025

-

Top 10 Benefits of Using Cobot Robots in Modern Manufacturing