How to Choose the Best Manufacturing Robots for Your Business?

Choosing the right manufacturing robots is a crucial decision for any business. With the rapid advancement of technology, the options can be overwhelming. Manufacturing robots vary in capabilities, from simple task automation to complex assembly processes. Each type has unique strengths and limitations.

When selecting manufacturing robots, consider specific needs. Evaluate the tasks that need automation. Think about the scale of production and the precision required. Not every robot fits every environment. Mistakes in this choice can lead to downtime or increased costs.

The market offers diverse solutions, but not all may suit your operation. Understanding your requirements is vital. Different sectors demand different types of robots. Some companies might focus on speed, while others prioritize flexibility. Reflecting on these factors will guide you toward the best decision for your manufacturing needs.

Understanding the Different Types of Manufacturing Robots Available

When considering manufacturing robots, it’s essential to grasp the varieties available.

Industrial robots, widely used in factories, excel in repetitive tasks.

They feature arms that adapt easily to different operations.

Collaborative robots, or cobots, work alongside humans.

They are designed for safety, allowing for close interaction.

These robots can enhance productivity without risking worker safety.

Another type is mobile robots.

They transport materials across the floor, reducing manual handling.

They can increase efficiency in logistics departments.

However, their integration can pose challenges.

For instance, navigating complex environments can lead to delays.

There are also specialized robots.

They are tailored for specific tasks, such as welding or painting.

While they offer precision, they require high initial investment and maintenance.

Consider your production needs carefully.

Evaluate the space and tasks at hand. Each type comes with advantages and constraints.

It's crucial to analyze all options.

Many businesses plunge into automation too quickly.

They overlook potential compatibility issues.

Reflecting on these factors can prevent costly mistakes in the future.

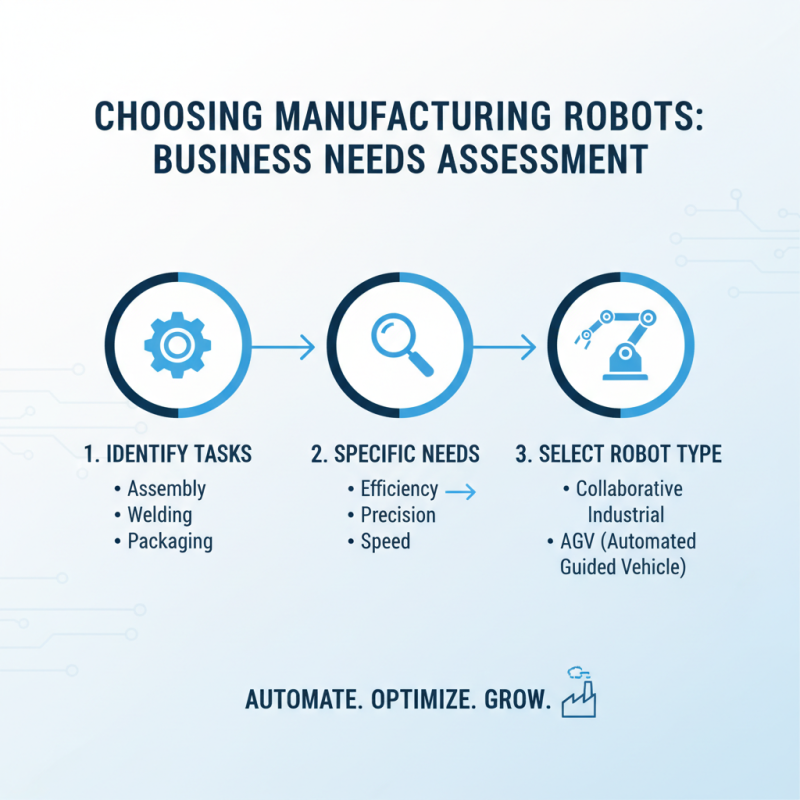

Assessing Your Business Needs and Production Goals

When choosing manufacturing robots, assessing your business needs is crucial. Identify the specific tasks you want the robots to perform. Are you looking for automation in assembly, welding, or packaging? Understanding these tasks helps narrow down options.

Production goals also play a key role. Consider your expected output and efficiency targets. What is your annual production volume? Are you aiming for flexibility or high speed? A clear vision of your goals informs better choices. However, it is easy to overlook potential limitations. Not every robot fits every environment or task.

Lastly, engaging your workforce in this transition is vital. They can provide insights on practical challenges. Do they see automation as a threat or an opportunity? Embracing their perspective can lead to smoother integration. Reflecting on these aspects helps ensure that your investment supports both current and future needs.

Evaluating the Technical Specifications and Features of Robots

When evaluating the technical specifications and features of manufacturing robots, it's crucial to focus on various aspects that matter most to your business. According to recent industry reports, over 70% of manufacturers emphasize precision and speed as key factors in their purchasing decisions. The right robot should offer a balance of quick cycle times and high accuracy to enhance production efficiency.

Payload capacity is another vital specification. Many robots can handle payloads ranging from a few kilograms to over 1,000 kilograms. Understanding your operational needs will help in selecting a robot that meets these requirements. Opting for a robot that is too weak may lead to frequent breakdowns. Conversely, choosing one far too powerful may simply be a waste of resources.

Software compatibility is equally important. As automation evolves, integration with existing systems can pose challenges. Currently, 60% of companies struggle with software issues. It is wise to prefer robots with user-friendly interfaces and robust support for popular programming languages. This helps streamline operations and reduces downtime. Reflecting on these specifications is essential for ensuring the right investment.

Comparison of Popular Manufacturing Robots Based on Key Features

Considering Safety, Maintenance, and Support Services

Choosing the right manufacturing robots is crucial for your business. When evaluating options, safety should be a top priority. According to the International Federation of Robotics, nearly 60% of workplace accidents involve machinery. Ensuring that robots come with safety features is essential. Look for certifications and built-in safety systems that protect both operators and equipment.

Maintenance plays a significant role in the long-term success of robotics. Research by the Robotics Industries Association shows that predictive maintenance can reduce downtime by up to 50%. Consider robots that offer easy access to parts and intuitive maintenance systems. Regular maintenance checks can prevent costly repairs later.

Tip: Train your team on maintenance best practices. Empower them to identify issues early.

Support services are often overlooked. Having access to a reliable support network can save time and money. Many manufacturers offer 24/7 support, which is invaluable during emergencies. Ensure that your chosen robot has adequate technical support options.

Tip: Check for the availability of online resources and detailed manuals. This can simplify troubleshooting.

How to Choose the Best Manufacturing Robots for Your Business?

| Robot Type | Safety Features | Maintenance Requirements | Support Services |

|---|---|---|---|

| Articulated Robots | Force limitation, safety light curtains | Regular lubrication, annual check-ups | 24/7 technical support, online troubleshooting |

| Collaborative Robots | 3D sensing, reduced torque | Minimal, easy component replacement | On-site training, customer support hotline |

| SCARA Robots | Interlocked safety covers, emergency stop | Occasional belt replacements, regular inspections | Email support, spare parts availability |

| Delta Robots | Safety enclosures, real-time monitoring | Low maintenance, periodic software updates | Remote diagnostics, dedicated support team |

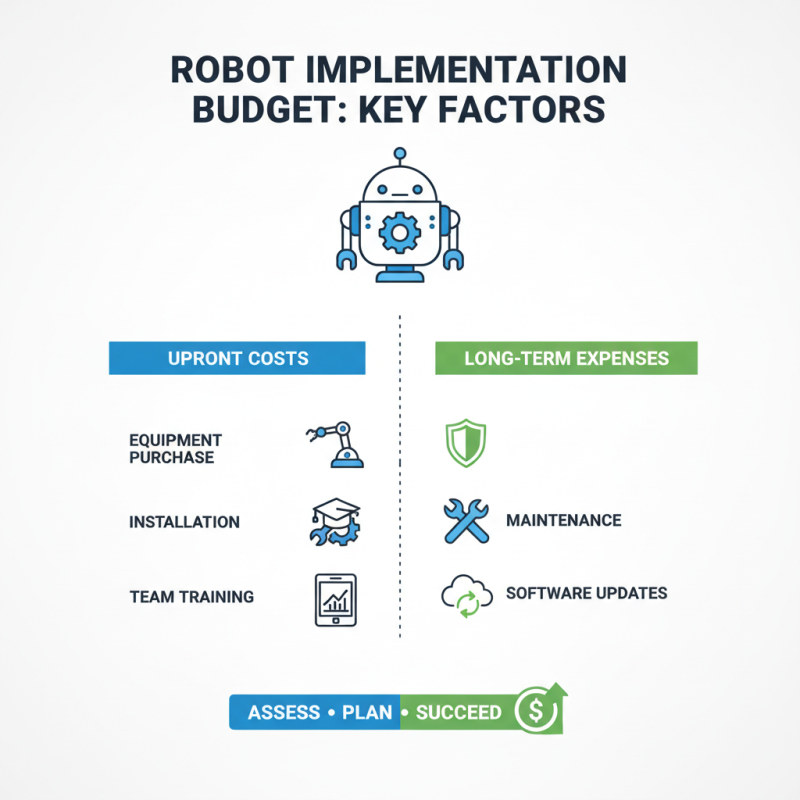

Determining Budget and Return on Investment for Robot Implementation

Determining a budget for robot implementation is crucial. Start by assessing upfront costs. This includes equipment purchase and installation. Don't forget about training costs for your team. Consider the long-term expenses too. Maintenance and software updates can add up over time.

It’s important to analyze the return on investment (ROI). How will these robots improve efficiency? Will they reduce labor costs? Make projections based on projected output. Include potential revenue increases and reduced downtime. This analysis can look promising but remember that real-world outcomes may vary.

While robots can enhance productivity, unexpected challenges may arise. Your team may face a learning curve. Not every implementation goes smoothly. Be prepared to adjust your strategies. Regular assessment of performance against your projections is key. Keep an open line of communication with your team throughout the process.

Related Posts

-

10 Best Robotics Automation Trends Transforming Industries in 2023

-

Unlocking the Future of Work with Robotics and Automation Trends and Innovations in 2023

-

Unlocking Efficiency: How Collaborative Robots are Transforming Modern Industries

-

Exploring the Future: How Robotics Software is Transforming Modern Industries

-

How to Leverage Robotic Automation Solutions for Streamlined Business Processes

-

Top 10 Benefits of Using Cobot Robots in Modern Manufacturing