How to Choose the Best Robot End of Arm Tooling for Your Automation Needs

In the realm of automation, the significance of choosing the right robot end of arm tooling cannot be overstated. As businesses increasingly turn to robotic solutions to enhance productivity and efficiency, the selection of appropriate tooling becomes a critical factor that can determine the success of automation projects. These tools, which are attached to the robotic arm, perform various functions including handling, assembling, and packaging, thereby directly influencing the quality of work and the overall operational workflow.

When contemplating the best robot end of arm tooling for specific automation needs, several factors must be taken into account. These include the type of materials being handled, the complexity of tasks, the required precision, and the environment in which the robots operate. Understanding these variables is essential for making informed decisions that align with the operational objectives of a business. Furthermore, advancements in technology have expanded the array of options available, allowing for tailored solutions that can enhance the performance of robotic systems.

Ultimately, the right choice of robot end of arm tooling can lead to significant improvements in productivity and efficiency, while also reducing operational costs and minimizing downtime. As industries evolve and automation becomes more prevalent, mastering the process of selecting the appropriate tooling will be an invaluable skill for engineers and decision-makers alike, shaping the future of manufacturing and other sectors.

Understanding the Basics of Robot End of Arm Tooling

The realm of robot end-of-arm tooling (EOAT) has become increasingly crucial in automating manufacturing processes. Understanding the basics of EOAT is essential for businesses looking to streamline production and enhance efficiency. EOAT refers to the devices attached to the end of robotic arms that enable them to interact with their environment, perform tasks, and carry objects. These tools vary greatly in design and function, ranging from grippers and suction cups to specialized tools for complex tasks like welding or assembly.

Industry reports suggest that the market for robotic EOAT is poised to grow at a compound annual growth rate (CAGR) of over 10% in the coming years, driven by advancements in manufacturing technology and the demand for automation across various sectors. As organizations seek to increase productivity, understanding the operational requirements of different EOAT choices becomes critical. Factors such as payload capacity, precision, and the specific applications for which the robotic arm will be used must guide the selection process.

**Tips for Choosing EOAT**: First, assess the types of materials and products being handled to match the EOAT with the application. For instance, if you’re handling delicate items, a soft gripper may be more suitable. Additionally, consider the compatibility of the EOAT with your existing robotic system to avoid costly retrofitting. Lastly, always evaluate the total cost of ownership, including maintenance and potential upgrades, to make an informed investment decision that aligns with your automation strategy.

How to Choose the Best Robot End of Arm Tooling for Your Automation Needs

| Tool Type | Weight Capacity (kg) | Grip Strength (N) | Material | Application | Flexibility |

|---|---|---|---|---|---|

| Vacuum Gripper | 5 | 50 | Rubber | Packaging | Moderate |

| Parallel Gripper | 10 | 80 | Aluminum | Assembly | High |

| Rotary Tool | 3 | 30 | Steel | Machining | Low |

| Magnetic Gripper | 15 | 150 | Composite | Metal Handling | Moderate |

| Force-Torque Sensor | N/A | N/A | Plastic | Quality Control | High |

Evaluating Your Automation Needs and Requirements

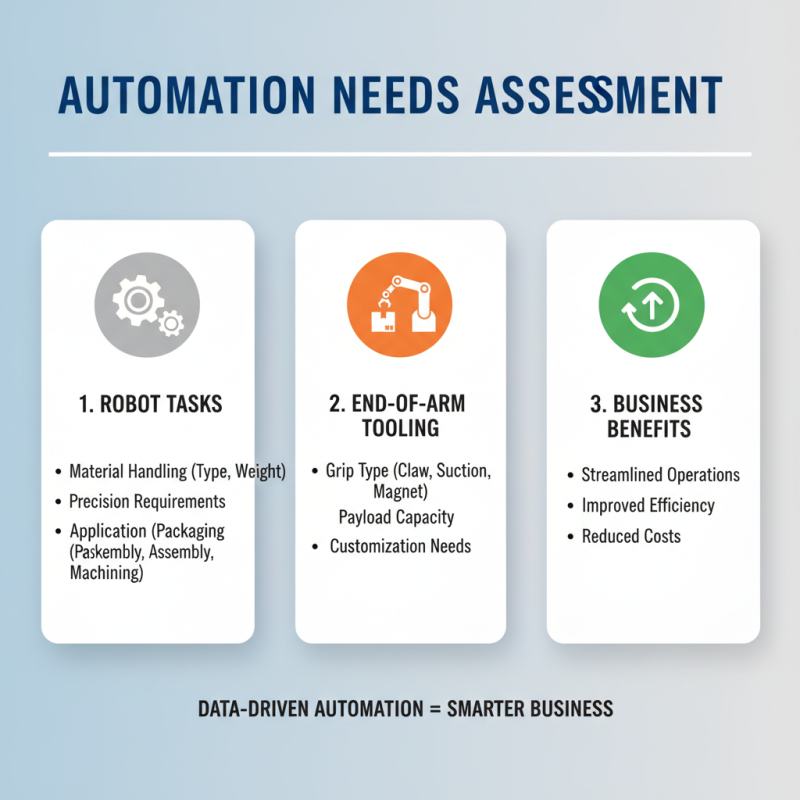

When evaluating your automation needs and requirements, it's essential to take a detailed look at the specific tasks your robot will perform. Understanding the nature of the materials being handled, the weight limits, and the precision required are fundamental aspects to consider. Different applications, whether it's packaging, assembly, or machining, will have unique demands that influence the choice of end of arm tooling. By conducting a thorough assessment of these factors, businesses can streamline their operations and improve efficiency.

**Tips:** Begin by mapping out your workflow processes. Identify key areas where automation could enhance productivity. Create a list of the tasks that the robot will need to perform, and obtain input from your team members who are directly involved with these processes. This collaboration can provide valuable insights into the specific requirements of the tooling.

Additionally, consider the future scalability of your operations. As your business grows, your automation tools may need to be adjusted or completely changed to accommodate new products or processes. By selecting end of arm tooling that offers flexibility and adaptability, you can ensure that your investment supports your long-term automation strategy, allowing for smoother transitions as your needs evolve.

Types of End of Arm Tools and Their Applications

When selecting the best robot end of arm tooling (EOAT) for automation needs, it is essential to understand the types of EOAT and their specific applications. Grippers are the most common type of EOAT, and they can be categorized into two main types: mechanical and pneumatic. Mechanical grippers are ideal for applications requiring precision and repeatability, commonly used in assembly lines where components need to be accurately positioned. According to a recent report by market analysts, the gripper market is expected to grow significantly, projected to increase by 12% annually through 2025, reflecting the rising demand for automation across various sectors.

Another significant category of EOAT is vacuum tools, which utilize suction power to handle delicate or non-porous items. This type of tooling is particularly beneficial in industries like packaging and electronics, where the risk of damaging products during handling is high. Data from industry studies indicate that vacuum tooling accounts for nearly 30% of the EOAT market, highlighting its importance in modern manufacturing processes. Moreover, specialized EOAT solutions, like custom-designed tooling, are increasingly becoming popular as manufacturers seek enhanced flexibility and compatibility with diverse applications, from food processing to automotive assembly lines. As robotics technology advances, understanding these various EOAT types will become crucial for companies looking to optimize their automation systems.

Factors to Consider When Selecting End of Arm Tooling

When selecting end of arm tooling (EOAT) for your automation needs, several critical factors must be taken into account. Firstly, it's essential to understand the specific tasks the robot will perform. Different applications, such as assembly, packaging, and material handling, require distinct tooling capabilities. Assess the weight and size of parts that will be handled, as well as the precision needed for the operation. This understanding will guide you in choosing an EOAT that enhances efficiency and achieves desired outcomes.

Another important consideration is the environment in which the robot will operate. Factors like temperature variations, exposure to chemicals, and the presence of dust or moisture can influence the material choice and design of the tooling. For instance, if the robot works in a cleanroom or harsh environment, selecting EOAT made from compatible materials that can withstand these conditions is crucial. Additionally, evaluate the ease of integration with existing systems. Your EOAT should not only fit the robot arm but also seamlessly connect with other equipment and software to ensure streamlined automation processes.

Best Practices for Implementing Robot End of Arm Tools

When implementing robot end of arm tooling (EOAT), the first step is to assess your specific automation requirements. Understanding the tasks the robot will perform is crucial to selecting the appropriate tooling. This involves considering the weight and size of objects, the type of handling required, and the necessary precision. Engaging in a thorough analysis of your workflow can help identify the optimal EOAT that aligns with your operational goals. Collaborating with a team that includes engineers and operators can provide insights into the most effective tooling solutions based on real-world applications.

Another best practice is to focus on flexibility and adaptability in your EOAT design. With the rapid evolution of automation technologies, having tools that can be easily modified or swapped can save time and resources in the long term. Consider investing in modular tooling systems that allow for quick adjustments without requiring extensive downtime for reconfiguration. Additionally, ensure that your EOAT can be easily integrated with your existing robotic systems without extensive redesign, which will enhance the overall efficiency and functionality of your automation setup. By emphasizing these best practices, you can streamline your operations while maximizing the potential of your robotic systems.

Automation Need Analysis: Robot End of Arm Tooling

Related Posts

-

Unlocking Efficiency: How Collaborative Robots are Transforming Modern Industries

-

How to Choose the Right Automation Systems for Your Business Efficiency

-

Top 10 Automation Systems for Efficient Business Operations in 2023

-

How to Leverage Robotic Automation Solutions for Streamlined Business Processes

-

What is Robotics and Automation Driving the Future of Industry with 25 Percent Growth by 2025

-

Unleashing Creativity in Robotics Engineering Courses for Future Innovators