10 Best Robotics Automation Trends Transforming Industries in 2023

In the rapidly evolving landscape of modern industry, robotics automation stands at the forefront of transformation, reshaping how businesses operate and deliver value. With advancements in technology and a growing demand for efficiency, various sectors are increasingly adopting robotic solutions to streamline processes. According to Dr. Emma Liu, a leading expert in robotics automation and the head of the Robotics Innovation Lab at Tech University, “The integration of robotics automation not only enhances productivity but also fosters innovation that redefines operational excellence.”

As we explore the ten best robotics automation trends transforming industries in 2023, it becomes evident that this technological revolution is not a distant future but a current reality. From manufacturing to healthcare, the applications of robotics are diverse and impactful, offering solutions that address labor shortages, improve precision, and reduce costs. Through this article, we will delve into the significant trends that are paving the way for smarter, more agile industries, underlining the essential role that robotics automation plays in shaping a competitive landscape.

Robotics Automation Trends Shaping Manufacturing Processes in 2023

The manufacturing industry is undergoing a profound transformation in 2023, driven by innovative robotics automation trends. One of the most significant trends is the increased implementation of collaborative robots, or cobots, that work alongside human operators. These intelligent machines enhance productivity by assisting with repetitive tasks, allowing human workers to focus on more complex and creative responsibilities. This synergy not only enhances efficiency but also fosters a safer work environment by minimizing the risk of workplace injuries.

Another key trend in robotics automation is the rise of smart manufacturing solutions that leverage artificial intelligence and machine learning. By utilizing advanced data analytics, manufacturers can optimize their operations in real-time, predict maintenance needs, and reduce downtime. This transition to data-driven decision-making is empowering companies to enhance their supply chain efficiency, ultimately leading to higher-quality products and customer satisfaction. As these automation technologies continue to evolve, they are set to redefine the landscape of manufacturing, driving both innovation and competitiveness in the industry.

Integration of AI and Machine Learning in Robotics Automation

The integration of artificial intelligence (AI) and machine learning (ML) into robotics automation is fundamentally altering the landscape of various industries in 2023. As AI technology advances, robots are becoming progressively smarter, capable of learning from their environments and making decisions in real-time. This evolution is driving efficiency and productivity, enabling systems to analyze vast amounts of data quickly and optimize operations dynamically. The ability of robots to adapt and learn reduces the need for human intervention, thereby lowering operational costs and minimizing human error in repetitive and hazardous tasks.

Moreover, AI and ML enhance the collaborative capabilities of robots within work environments. These technologies enable robots to work alongside humans more intuitively, understanding and predicting actions. This symbiotic relationship enhances safety, as robots can quickly adapt their behavior based on their human counterparts. The deployment of smart robots equipped with AI and ML capabilities is revolutionizing sectors such as manufacturing, healthcare, and logistics, where precision and efficiency are critical. As these technologies continue to advance, the potential for robotics automation to reshape industries and improve overall operational efficiency remains significant.

10 Best Robotics Automation Trends Transforming Industries in 2023

Integration of AI and Machine Learning in Robotics Automation

| Trend | Description | Impact on Industry | Key Benefits |

|---|---|---|---|

| Collaborative Robots | Robots designed to work alongside humans. | Manufacturing, logistics. | Increased efficiency, safety. |

| AI-Powered Robotics | Integration of AI for enhanced decision making. | Healthcare, agriculture. | Improved accuracy, adaptability. |

| Robotics Process Automation (RPA) | Use of software robots to automate repetitive tasks. | Finance, customer service. | Cost savings, increased speed. |

| Swarm Robotics | Use of multiple robots to perform tasks collaboratively. | Logistics, search & rescue. | Scalability, efficiency. |

| Robotics in Healthcare | Robots assisting in surgeries and patient care. | Surgery, rehabilitation. | Reduced recovery time, improved outcomes. |

| Drones in Delivery | Use of drones for package delivery. | Retail, e-commerce. | Faster delivery, reduced costs. |

| Smart Factories | Integration of IoT and robotics in manufacturing. | Manufacturing. | Enhanced production, flexibility. |

| AI-Driven Quality Control | Use of AI to inspect products for quality. | Manufacturing, food sector. | Reduced waste, improved standards. |

| Autonomous Vehicles | Self-driving technology for transport and delivery. | Transportation, logistics. | Reduced human error, efficiency. |

| Telepresence Robotics | Robots that enable remote interaction. | Education, corporate environments. | Enhanced communication, accessibility. |

Collaborative Robots Enhancing Workforce Efficiency in Various Industries

Collaborative robots, or cobots, are revolutionizing workforce dynamics across various industries by enhancing efficiency and productivity. Unlike traditional industrial robots, which usually operate independently in isolated environments, cobots are designed to work alongside humans, sharing tasks and responsibilities. This collaborative approach allows businesses to optimize their operations by integrating human creativity and problem-solving capabilities with the precision and strength of robotic systems.

One major advantage of incorporating cobots into the workplace is their ability to adapt to various tasks and environments. For instance, in manufacturing settings, cobots can take over repetitive tasks such as assembly, packaging, or quality inspection, allowing human workers to focus on more intricate and value-added activities. This not only increases overall productivity but also improves job satisfaction as employees can engage in more meaningful work.

**Tips:** When considering the adoption of collaborative robots, businesses should start small by identifying specific tasks that are repetitive and time-consuming. Begin with pilot projects to measure effectiveness and gather feedback from workers, ensuring a seamless integration process. Additionally, investing in training for employees on how to work alongside cobots can enhance collaboration and optimize workflow efficiency.

Impact of Collaborative Robots on Workforce Efficiency by Industry in 2023

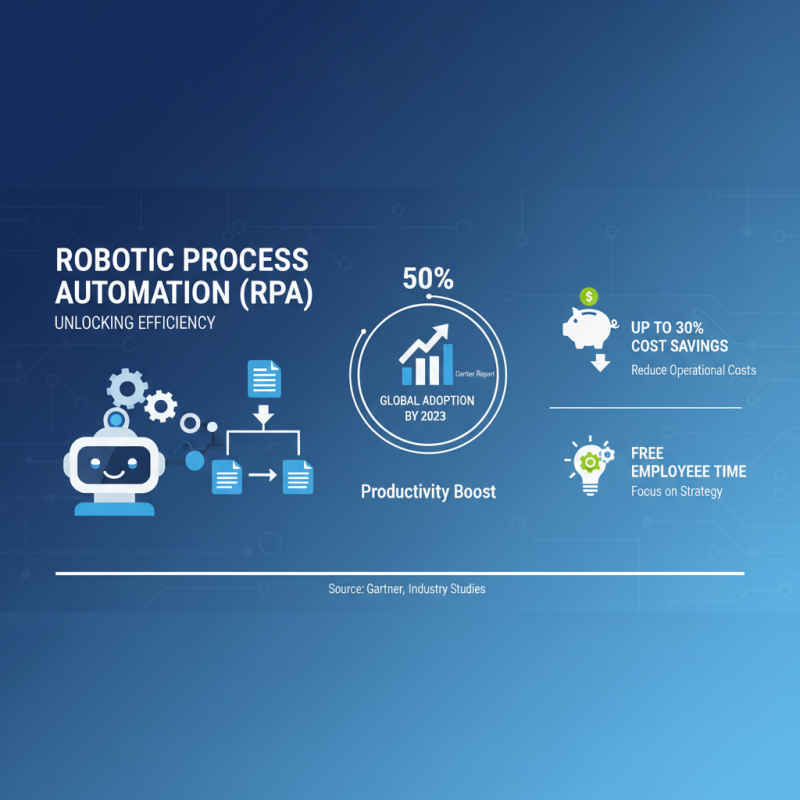

Advancements in Robotic Process Automation for Business Operations

In recent years, Robotic Process Automation (RPA) has emerged as a key driver of efficiency and productivity in business operations. According to a report by Gartner, more than 50% of organizations globally are expected to adopt some form of RPA by the end of 2023, demonstrating the technology's growing importance across various sectors. RPA can significantly reduce operational costs, with studies indicating potential savings of up to 30% in process execution. By automating repetitive and mundane tasks, businesses are unlocking valuable employee time that can be redirected towards more strategic initiatives.

Moreover, advancements in RPA technology are leading to more sophisticated automation solutions, integrating artificial intelligence and machine learning capabilities. A joint report by McKinsey and PwC projects that by 2025, intelligent automation, which combines RPA with cognitive technologies, could potentially contribute between $6.8 trillion and $11.9 trillion to the global economy. This transformative power of RPA is not only streamlining processes but also enhancing accuracy and compliance, thus reducing errors that can arise from manual task handling. As industries continue to evolve, the strategic implementation of RPA is becoming foundational to thriving in an increasingly competitive landscape.

Impact of Robotics Automation on Supply Chain Management and Logistics

The impact of robotics automation on supply chain management and logistics is profound and increasingly essential for businesses aiming to enhance efficiency and reduce operational costs. According to a recent report by McKinsey, the implementation of robotics in logistics is expected to improve supply chain efficiencies by up to 20-30% while lowering labor costs by as much as 40%. With automated systems handling tasks such as inventory management, sorting, and transportation, organizations can streamline processes, minimize human error, and respond more rapidly to market demands.

One significant trend is the increasing use of collaborative robots (cobots) that work alongside human workers in warehouses and distribution centers. Cobots not only assist in repetitive tasks but also empower employees to focus on more strategic roles. Data from the World Economic Forum indicates that the adoption of such technologies is set to create approximately 12 million new jobs by 2025, despite concerns about job displacement. This highlights the transformative potential of robotics in enhancing workforce productivity and adaptability to evolving market landscapes.

Tips: To maximize the benefits of robotics in supply chain management, businesses should invest in training programs that prepare their workforce to collaborate effectively with automated systems. Additionally, companies should adopt a phased integration approach, starting with pilot projects to evaluate the impact and scalability of robotic solutions. Continuous assessment and feedback loops will ensure that the implementation of robotics aligns with overall business objectives and enhances operational sustainability.

Related Posts

-

Unlocking the Future of Work with Robotics and Automation Trends and Innovations in 2023

-

What is Robotics and Automation Driving the Future of Industry with 25 Percent Growth by 2025

-

Unlocking Efficiency: How Collaborative Robots are Transforming Modern Industries

-

How to Effectively Implement Collaborative Robots in Manufacturing Processes

-

Exploring the Future: How Robotics Software is Transforming Modern Industries

-

How to Leverage Robotic Automation Solutions for Streamlined Business Processes