2026 Best Robotic Systems Innovations to Transform Industries?

As industries face rapid changes, robotic systems stand at the forefront of innovation. Renowned expert Dr. Elaine Carter states, “Robotic systems are not just tools; they are catalysts for change.” This insight highlights how these technologies redefine processes across sectors.

In 2026, we will likely see groundbreaking advancements. Robotics are evolving, but challenges remain. Automation may lead to job displacement, raising important questions about workforce adaptation. Industries must embrace these systems while also addressing the potential fallout.

Moreover, safety and ethical concerns linger around robotic systems. As we adopt these technologies, we must reflect on their societal impact. Achieving balance is crucial. The innovations in 2026 promise transformation, but we must navigate the complexities they introduce. The journey ahead demands careful consideration and proactive engagement.

Future Trends in Robotic Systems for Industrial Transformation

In the rapidly changing landscape of manufacturing, robotic systems are at the forefront. The future of industrial transformation hinges on innovative technologies. Collaborative robots, or cobots, are gaining traction. They work alongside humans, enhancing productivity without compromising safety. Their ability to adapt to various tasks allows for flexibility in production lines. However, integration challenges exist. Some workers resist this change, fearing job loss.

Another promising trend is the use of AI-driven robotics. These systems can analyze vast amounts of data in real-time. They help predict maintenance needs, reducing downtime. However, reliance on AI raises questions about decision-making. Humans must remain in the loop to ensure ethical considerations are met. Moreover, the steep learning curve for implementation can be daunting for many companies.

Automation is advancing, but not without its flaws. The technology can malfunction, leading to delays and increased costs. Companies must carefully balance automation and human input. Emphasizing training for workers ensures they feel valued and can adapt. A thoughtful approach to robotic integration will ultimately shape the industries of tomorrow.

Key Innovations in Robotic Technology for 2026

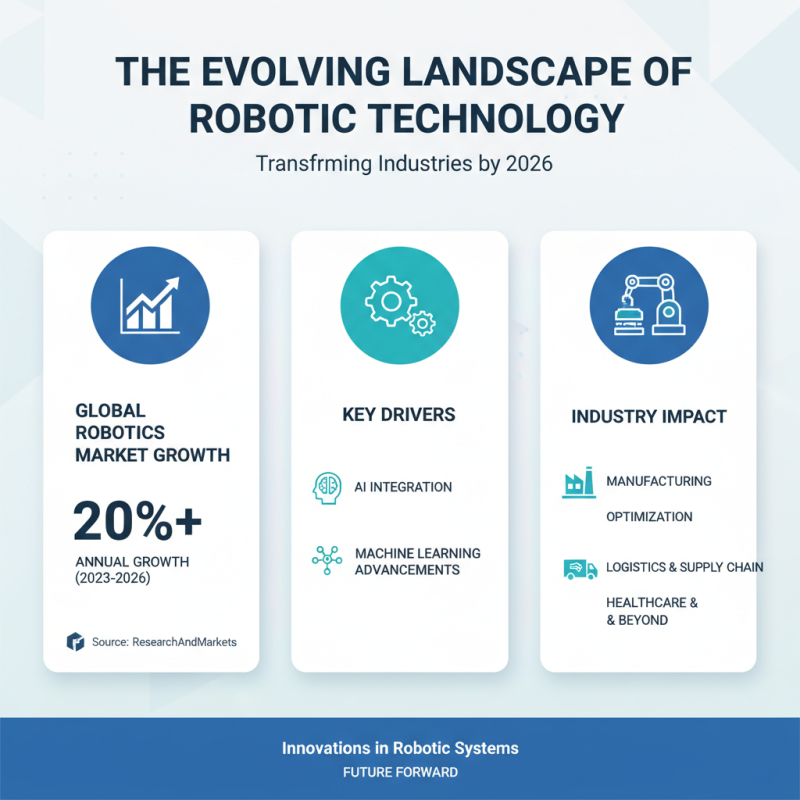

The landscape of robotic technology is evolving rapidly. By 2026, innovations in robotic systems are set to transform industries in profound ways. According to a recent industry report by ResearchAndMarkets, the global robotics market is expected to grow by over 20% annually. This rapid growth reflects significant advancements in AI and machine learning integration.

Key innovations in robotics include enhanced automation processes. Robots are increasingly capable of sophisticated tasks, from intricate assembly in manufacturing to precision surgeries in healthcare. Collaborative robots, or cobots, will witness increased deployment on factory floors. They work safely alongside human workers, boosting productivity while reducing injury risks. However, companies must address the challenges of training and integrating these systems effectively.

Another exciting trend is the rise of autonomous drones. They are already altering logistics and agriculture. In 2026, we may see widespread use in delivery services, helping reduce transportation costs. Still, issues regarding regulation and air traffic management need further attention. The potential is huge, but there are hurdles to overcome to ensure safety and efficiency in their operation.

Impact of Robotics on Manufacturing Efficiency and Productivity

The impact of robotics on manufacturing efficiency and productivity is profound. Automated systems streamline processes. This reduces human error and increases output. For example, robots can complete tasks quicker than human workers. They operate tirelessly, ensuring that production runs around the clock. This capability leads to significant cost savings.

However, the transition to robotics is not without challenges. Workers may feel threatened by automation. Training becomes essential to ensure a smooth integration of robotic systems. Some employees might struggle to adapt. Management should focus on effective communication. Addressing fears can help ease transitions.

Tips: Invest in employee training programs. This helps workers understand robotic systems better. Regularly update your team on developments. Encourage feedback on how robotics influence their daily tasks. Stay adaptable and open to change.

Applications of Advanced Robotics Across Various Industries

Advanced robotics is reshaping various industries with innovative applications. In manufacturing, robots are enhancing productivity and quality. They can perform repetitive tasks faster and with precision. This leads to fewer errors and reduced waste. However, this shift may leave some workers feeling displaced. It’s crucial to consider retraining programs for affected employees.

In healthcare, robotic systems assist in surgeries and patient care. They enable minimally invasive procedures, resulting in quicker recovery times. Robots also help in delivering medications and monitoring patients. Yet, reliance on technology raises questions about compassion and human touch. The balance between efficiency and empathy is essential for patient satisfaction.

The logistics sector benefits significantly from automation. Robots streamline warehouse operations and optimize shipping processes. They handle inventory with accuracy and speed. However, challenges persist in integrating these systems with existing workflows. Companies must address concerns about cybersecurity and data privacy. Advanced robotics presents opportunities and hurdles that require thoughtful solutions.

Challenges and Solutions in Implementing Robotic Innovations

The integration of robotic innovations in various industries presents notable challenges. One significant issue is workforce adaptation. Employees may fear losing their jobs. Training programs are often inadequate. This gap leads to resistance among staff. The disparity between robot capabilities and human skills requires attention.

Another challenge lies in technical integration. Many systems operate in isolation. Communication between robots and existing infrastructure is limited. This can slow down operations and reduce efficiency. Companies must invest in compatible technology. This investment can strain budgets, particularly for smaller businesses.

Moreover, ethical concerns arise with increased automation. Decisions made by robots can lead to consequences. Unintended bias may affect operations. Transparency in robotic decision-making is essential. It’s crucial to ensure these innovations benefit society as a whole. Addressing these challenges head-on can drive progress, yet reflection on the implications remains necessary.

2026 Best Robotic Systems Innovations to Transform Industries - Challenges and Solutions in Implementing Robotic Innovations

| Innovation Area | Description | Challenges | Solutions | Impact on Industry |

|---|---|---|---|---|

| Autonomous Delivery Robots | Robots designed for last-mile delivery in urban environments. | Regulatory hurdles and urban navigation challenges. | Collaboration with local governments and advanced navigation systems. | Enhanced logistics efficiency and reduced delivery times. |

| AI-Powered Manufacturing Robots | Robots that utilize AI for adaptive manufacturing processes. | High initial costs and the need for skilled workforce. | Investment in training and phased implementation strategies. | Greater customization and faster production cycles. |

| Collaborative Robots (Cobots) | Robots designed to work alongside human workers safely. | Safety concerns and worker acceptance. | Extensive training and incremental integration into workflow. | Increased productivity and enhanced worker safety. |

| Agricultural Robots | Robots capable of planting, watering, and harvesting crops. | Variable field conditions and high operational costs. | Development of versatile and cost-effective robotic systems. | Improved crop yield and reduced labor shortages. |

| Healthcare Robots | Robots aiding in surgery, rehabilitation, and patient assistance. | Regulatory compliance and integration with existing systems. | Rigorous testing and gradual integration with healthcare practices. | Enhanced surgical precision and patient care efficiency. |

Related Posts

-

Unlocking the Future of Work with Robotics and Automation Trends and Innovations in 2023

-

What is Robotics and Automation Driving the Future of Industry with 25 Percent Growth by 2025

-

What is Robot Technology and How is it Transforming Our Lives Today

-

10 Best Robotics Automation Trends Transforming Industries in 2023

-

Top 10 Tips for Implementing Robotic Systems in Your Business Successfully

-

Unlocking Efficiency: How Collaborative Robots are Transforming Modern Industries