10 Best Manufacturing Robots for Efficient Production in 2026?

As the world of industrial production evolves, the role of manufacturing robots becomes increasingly critical. In 2026, analysts project that the market for manufacturing robots will reach over $20 billion, highlighting a shift toward automation in factories. According to a recent report from the International Federation of Robotics, manufacturing robots can increase production efficiency by up to 30%. This dramatic growth reflects the industry's need for precision and speed.

Expert in robotics, Dr. Emily Chen, emphasizes, "Manufacturing robots are not just tools; they are integral to modern production strategies." Her insights reveal that integrating robotic systems can lead to significant cost savings and improved quality control. Despite the remarkable advancements, there are challenges. Companies often struggle with the initial investment and training required for their workforce.

The necessity for adaptation remains pressing. As manufacturers look to these technological solutions, a careful examination is essential. What obstacles do businesses face? How do they ensure their teams work harmoniously with these machines? The answers will shape the future of manufacturing robots.

Overview of the Manufacturing Robot Market Trends Leading to 2026

The manufacturing robot market is evolving rapidly as we approach 2026. Advanced robotics technology will drive improvements in efficiency and productivity. This trend is notable across various industries, including automotive and electronics. Automation will streamline production lines while reducing labor costs.

Collaborative robots, or cobots, will also gain traction, allowing humans and machines to work together more safely.

However, this shift to automation raises concerns. There is apprehension surrounding job displacement. Workers may need retraining to stay relevant in a technology-driven market. Not all manufacturers are prepared for this transition. Some companies might struggle to integrate new technologies into existing systems. Additionally, cybersecurity remains an ongoing threat as more robots connect to the Internet.

As businesses explore automation, they must consider the balance between efficiency and human touch. Smart manufacturing needs to embrace technology without fully sidelining the workforce. Adapting to the future means making tough choices and addressing these complexities. The role of human oversight may evolve, becoming a safeguard in the interplay of innovation and production.

Key Features and Technologies Driving Robot Efficiency in Production

The landscape of manufacturing robots is rapidly evolving. As of 2026, several key technologies are enhancing robot efficiency in production environments. Automation continues to dominate, with reports indicating that 85% of manufacturers plan to increase their automation efforts. This shift is driven by the need for higher productivity and reduced labor costs. Many robots are now equipped with advanced sensors and artificial intelligence, allowing them to adapt to varying tasks with remarkable precision.

Collaboration between robots and human workers is also on the rise. Collaborative robots, or cobots, enable safer workflows. They can work alongside humans in tight spaces without the need for safety cages. This integration not only improves efficiency but also creates a more flexible production line. According to a recent study, factories using cobots reported a 20% increase in overall productivity.

However, the implementation of these advanced technologies is not without challenges. Many manufacturers face difficulties in integrating robots into existing systems. Training staff to work effectively with new automation tools can be time-consuming. Moreover, there is a constant need to balance efficiency gains with job security. Such complexities require careful planning and reflection. In this innovative age, ongoing assessment of robot performance and workplace dynamics is critical.

10 Best Manufacturing Robots for Efficient Production in 2026

| Robot Model | Key Features | Technology Used | Efficiency Rate (%) | Payload Capacity (kg) |

|---|---|---|---|---|

| Model A | Multi-tasking capabilities, AI integration | AI, Machine Learning | 95 | 150 |

| Model B | Precision handling, Vision systems | Computer Vision, Sensors | 92 | 100 |

| Model C | Collaborative operation, Safety sensors | Collaboration Technology | 90 | 200 |

| Model D | High-speed operation, Modular design | Modular Robotics | 97 | 80 |

| Model E | Enhanced flexibility, Self-learning | Adaptive Algorithms | 93 | 120 |

Top 10 Manufacturing Robots with Data-Driven Performance Metrics

Manufacturing robots are revolutionizing production efficiency. By 2026, the best models will integrate seamless data-driven performance metrics. These metrics help in monitoring tasks in real-time. They allow manufacturers to identify bottlenecks quickly. Fast adjustments can often mean the difference between profit and loss.

When selecting a robot, consider its adaptability. Some robots may excel in certain tasks but struggle with others. It’s essential to understand your production needs. Data analytics will inform you which tasks could benefit from automation. Streamlining operations requires careful thought. Sometimes, what seems efficient may require further testing and adjustment.

Tip: Always keep an open communication line with your team. They can provide insights into how robots impact workflow. Observing the human-robot interaction can offer valuable feedback. Remember, technology evolves rapidly. Staying updated is crucial for maximizing efficiency.

Top 10 Manufacturing Robots Performance Metrics for 2026

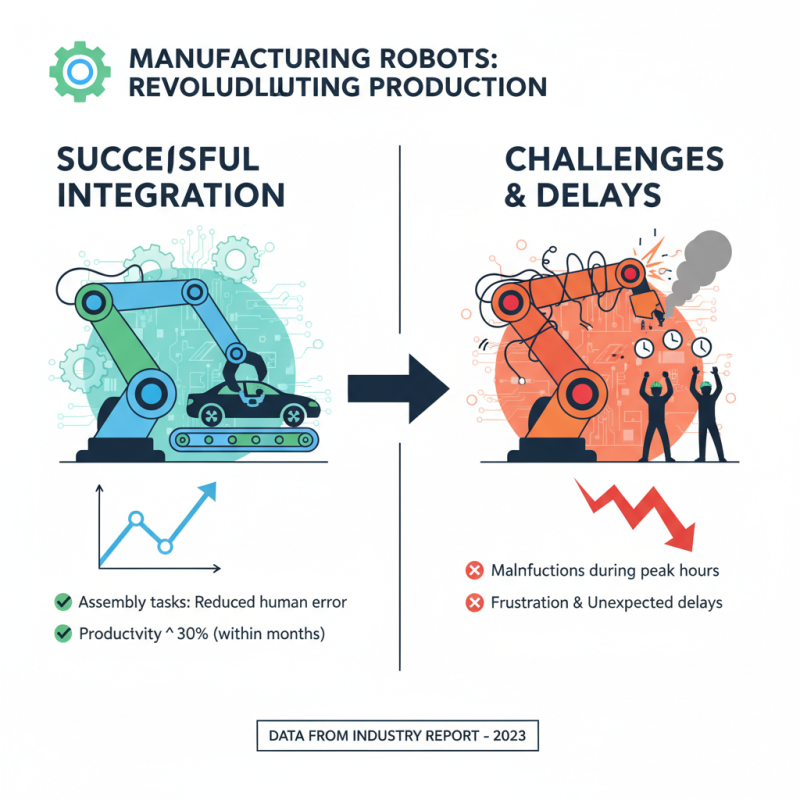

Industry Case Studies: Successful Implementation of Manufacturing Robots

Manufacturing robots have transformed production lines across various industries. One company integrated robotic arms for assembly tasks, drastically reducing human error. Their productivity soared by 30% within months. However, not all transitions are seamless. Some workers faced challenges, as the robots often malfunctioned during peak hours. This caused frustration and led to unexpected delays.

In another case, a factory implemented automated guided vehicles (AGVs) for material transport. The AGVs enhanced workflow efficiency, yet employees reported concerns about job security. While automation streamlines processes, it sometimes creates tension within teams. Companies need to address these sentiments as they adopt advanced technologies. Balancing efficiency and workforce morale remains a challenge for many manufacturers.

Through these examples, it becomes clear that the road to automation is complex. Companies must analyze their unique contexts. Success isn’t just about choosing the latest technology; it’s about nurturing a collaborative environment. Real-world applications highlight the need for training and support as robots become integral to production.

Projected Cost Savings and ROI of Using Robots in Production Processes

In recent years, manufacturing robots have transformed production processes. By 2026, investing in such robots can lead to significant cost savings. Companies often see reduced labor costs as robots can work around the clock. This relentless efficiency can boost overall productivity.

Tips: Analyze your production needs before choosing a robot. Not every robot fits every task. Focus on your specific requirements.

With the right robots, manufacturers can expect a substantial return on investment (ROI). Notably, the initial investment may seem high. However, the savings in labor and the increase in production capacity often compensate for these costs over time. Businesses should carefully evaluate all costs involved, including maintenance and training.

Tips: Regular maintenance is crucial. Neglected robots can incur higher costs than expected. Always plan for unexpected repairs.

It's vital to consider the learning curve that comes with new technology. Employees might need training to adapt to robotic systems. Some may resist these changes, fearing job loss. Open communication about changes can help ease their concerns and foster a better work environment.

Related Posts

-

Unlocking the Future of Work with Robotics and Automation Trends and Innovations in 2023

-

What is Robotics and Automation Driving the Future of Industry with 25 Percent Growth by 2025

-

2026 Best Robotic Systems Innovations to Transform Industries?

-

2025 How to Choose the Right Collaborative Robot Arm for Your Business

-

Top Benefits of Manufacturing Robots in Modern Production Industries

-

10 Best Robotics Automation Trends Transforming Industries in 2023