Top Benefits of Manufacturing Robots in Modern Production Industries

In today's fast-paced industrial landscape, the integration of manufacturing robots has emerged as a pivotal element for enhancing productivity and operational efficiency. According to a recent report by the International Federation of Robotics, the deployment of manufacturing robots is projected to grow by 15% annually over the next five years, highlighting their critical role in modern production environments. This impressive growth is largely driven by the need for increased precision, reduced labor costs, and the ability to operate continuously without compromising quality.

As noted by Dr. Emily Chen, a leading expert in robotics and automation, “Manufacturing robots not only optimize production lines but also empower businesses to reallocate human resources towards more strategic tasks, fostering innovation and improving overall workplace dynamics.” This perspective underscores the transformative potential of manufacturing robots, which are no longer viewed merely as tools, but as integral partners in achieving business objectives. Their capabilities extend beyond traditional manufacturing processes, enabling companies to remain competitive in an increasingly globalized market.

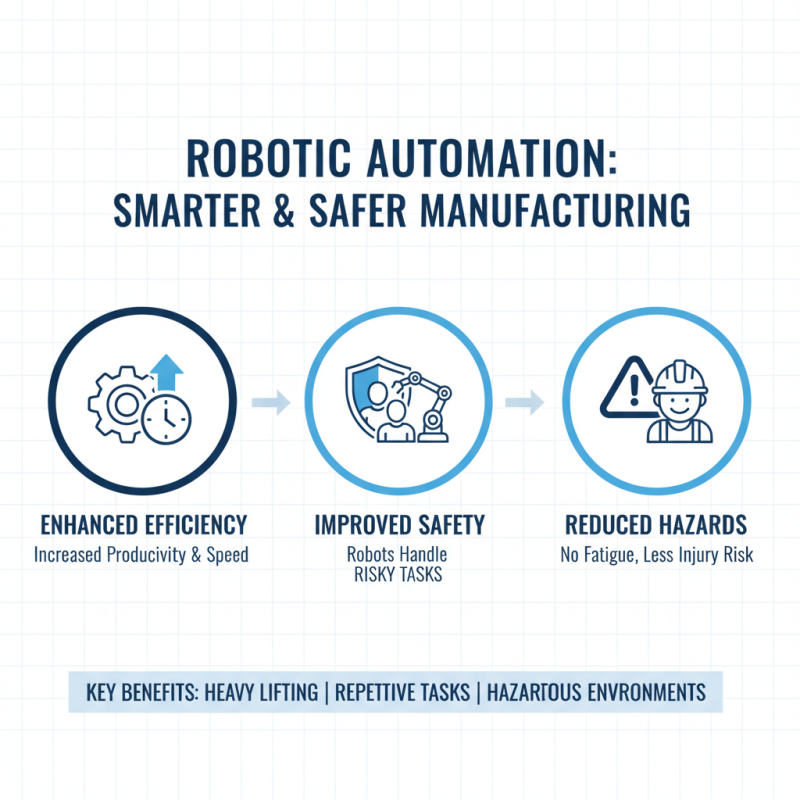

The benefits of adopting manufacturing robots are manifold, encompassing improved safety, enhanced product quality, and significant savings in operational costs. As industries continue to evolve, it becomes imperative for manufacturers to embrace this technological evolution to secure a sustainable future in production.

Advantages of Increased Efficiency Through Manufacturing Robots

The adoption of manufacturing robots has transformed production industries, leading to significant increases in operational efficiency. According to a report by the International Federation of Robotics (IFR), the implementation of robotics in manufacturing can boost productivity by up to 30%. This enhancement is largely due to the ability of robots to operate continuously, without fatigue, and perform high-precision tasks with consistent quality. As a result, businesses can meet customer demands promptly while also minimizing waste and reducing production costs.

Furthermore, robots play a crucial role in optimizing workflow within manufacturing environments. The McKinsey Global Institute found that automation, including the use of robots, could increase labor productivity by 50% in the manufacturing sector. This increase not only allows for better resource allocation but also enables human workers to focus on more complex and creative tasks, ultimately fostering innovation. As production lines become more digitalized, the integration of robots becomes essential for maintaining competitive advantages.

**Tip:** When considering the integration of manufacturing robots, it is vital to conduct a thorough analysis of current workflows to identify areas where automation can provide maximum benefit. Implementing pilot programs can also help in evaluating the impact of robotics before full-scale deployment.

**Tip:** Regular training and upskilling of your workforce are crucial when introducing robotics. As technology evolves, ensuring your team is equipped with the necessary skills can enhance productivity and innovation within your organization.

Top Benefits of Manufacturing Robots in Modern Production Industries - Advantages of Increased Efficiency Through Manufacturing Robots

| Benefits | Description | Impact on Efficiency (%) |

|---|---|---|

| Increased Production Speed | Robots can operate faster than human workers, significantly reducing production time. | 25% |

| Enhanced Precision | Robots perform tasks with high accuracy, reducing defects and rework. | 20% |

| 24/7 Operation | Robots can work continuously without breaks, increasing overall output. | 30% |

| Improved Worker Safety | Robots take over hazardous tasks, lowering the risk of workplace injuries. | 15% |

| Cost Reduction | Automating processes can lower labor costs and increase profit margins. | 18% |

Reduction in Labor Costs Associated with Automation Technology

The integration of manufacturing robots in modern production industries has led to a significant reduction in labor costs, primarily due to the efficiency and precision that automation technology brings to the production line. According to a report from the International Federation of Robotics, companies that adopted automation saw their overall labor costs decrease by an average of 30%. This drastic reduction is a result of robots performing repetitive tasks more efficiently than human workers, thus allowing businesses to allocate their labor to more complex and creative tasks, which can enhance productivity and innovation.

Furthermore, the use of manufacturing robots also minimizes downtime associated with training and onboarding new employees, which is often a hidden cost in labor expenses. A study by McKinsey & Company indicates that automating production tasks can lead to a decrease in the total number of labor hours required by nearly 50% in sectors like automobile manufacturing. This not only lowers direct labor costs but also helps in stabilizing operating expenses, providing businesses with greater flexibility to respond to market demands without compromising quality. The long-term financial benefits, combined with enhanced operational efficiency, highlight why industries are increasingly investing in robotic automation as a strategic initiative to improve their bottom line.

Consistent Quality Control Achieved via Robotic Precision

The integration of robots in manufacturing has revolutionized quality control across various production industries. According to a report by McKinsey & Company, organizations that implement robotic automation achieve up to 95% accuracy in their production processes. This precision minimizes human errors and variations, leading to more consistent product quality. When robots perform repetitive tasks, they maintain the same level of high performance throughout their operational life, which significantly reduces defects and rework costs.

Furthermore, the 2021 World Economic Forum report indicates that manufacturing facilities using robotics can reduce their production time by 30-50%, while simultaneously enhancing product quality. This accelerated pace does not compromise standards; on the contrary, robots equipped with advanced sensors and artificial intelligence systems can monitor and adjust production protocols in real-time. This capability allows manufacturers to detect anomalies instantly, thus ensuring that each product meets stringent quality benchmarks before reaching the market. As industries continue to embrace automation, the reliance on robotic precision for consistent quality control is set to become a cornerstone of modern production strategies.

Safety Enhancements in the Workplace with Robotic Integration

Robotic integration in modern manufacturing not only enhances efficiency but significantly improves workplace safety. One of the primary benefits is the ability of robots to take on dangerous tasks that pose risks to human workers. For instance, robots can handle heavy lifting, perform repetitive actions, and navigate hazardous environments without the dangers of fatigue or injury. This technology alleviates human exposure to potential accidents, contributing to a safer work environment.

Tips for implementing robotic systems focus on meticulous planning and training. First, assess the specific tasks that are most hazardous and evaluate how robots can safely manage these processes. Next, invest in comprehensive training for the workforce to ensure they understand how to work alongside robots effectively. This collaboration can lead to an enhanced safety culture within the workplace, where human workers feel supported and protected by their robotic counterparts.

Additionally, regular maintenance and updates of robotic systems play a critical role in ensuring ongoing safety enhancements. By keeping equipment in top condition, companies can mitigate risks associated with robotic failures or malfunctions. Implementing scheduled check-ups creates a reliable manufacturing environment, promoting safety and efficiency hand in hand.

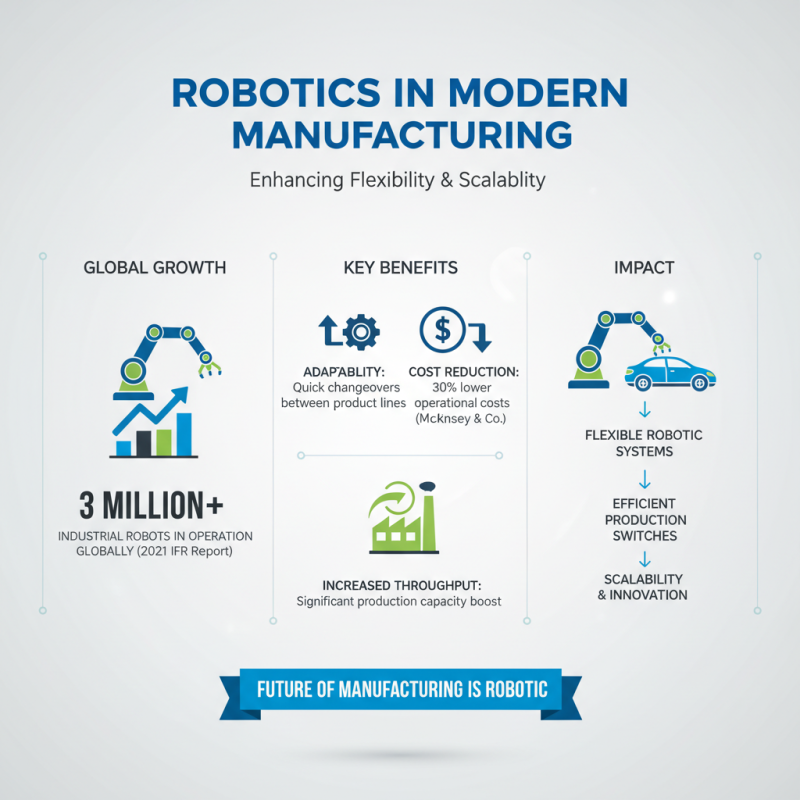

Flexibility and Scalability Offered by Modern Robotics in Production

Modern production industries increasingly leverage robotics to enhance flexibility and scalability in manufacturing processes. According to a report by the International Federation of Robotics (IFR), the global stock of industrial robots reached 3 million units in operation by 2021, underscoring their growing importance in various sectors. This rise is largely attributed to the ability of robots to quickly adapt to changes in production demand, allowing manufacturers to efficiently switch between different product lines without extensive reconfiguration. For instance, a study by McKinsey & Company revealed that companies utilizing flexible robotic systems could achieve a 30% reduction in operational costs while significantly increasing their production throughput.

Additionally, the scalability provided by modern robotics cannot be understated. With the integration of artificial intelligence and machine learning, robots are now capable of handling both high-volume production and low-volume bespoke manufacturing. According to a report from Boston Consulting Group, businesses that adopt robotics in their production lines can scale operations up or down without needing to invest heavily in new infrastructure. This adaptability not only reduces lead times but also enables firms to respond swiftly to shifting market demands, fostering a more agile manufacturing environment. Such capabilities are vital for companies seeking to maintain a competitive edge in an increasingly dynamic global marketplace.

Related Posts

-

Unlocking Efficiency: How Collaborative Robots are Transforming Modern Industries

-

Unlocking the Future of Work with Robotics and Automation Trends and Innovations in 2023

-

What is Robotics and Automation Driving the Future of Industry with 25 Percent Growth by 2025

-

What is Robotics Software? Understanding Its Benefits and Applications

-

Unleashing Creativity in Robotics Engineering Courses for Future Innovators

-

Why Robotic Process Automation Software is Essential for Achieving 40% Operational Efficiency Gains in 2023